New Nanoprinting Method with Metalenses to Speed Up 3D Fabrication and Support Large-Scale Materials Research

A team of 18 researchers has developed a high-speed method for printing precise three-dimensional (3D) structures at the nanoscale. This breakthrough could accelerate advances in microelectronics and biomedicine, and spur the development of the next generation of nanomaterials.

The study published in Nature is a culmination of 5 years of work and includes research from UNC Charlotte Klein College of Science co-author You Zhou, assistant professor of physics and optical science.

Fast and Complex

The new 3D printing system uses large arrays of “metalenses,” which are ultrathin optical devices made from nanoscale patterns, to generate more than 120,000 laser focal points at once. Each focal point acts like a tiny pen, solidifying a photosensitive resin to build precise structures, layer by layer.

Researchers leveraged two capabilities enabled by metalenses: high-numerical aperture metalenses for sharp focusing and large arrays for high-throughput printing. The new two-photon lithography (TPL) platform prints nanoscale features in parallel to reach speeds above 120 million voxels per second, roughly 1000 times faster than conventional TPL systems.

The arrays are paired with an ultrafast laser and a spatial light modulator that enables researchers to adjust the brightness of each focal point independently. That control allows the printer to switch individual spots on or off and fine-tune line widths to create complex 3D shapes with feature sizes down to 113 nanometers.

Overcoming Limits in Nanoscale Printing

The research addresses a major constraint that has limited TPL for decades: the small field of view of conventional microscope objectives, which restricts the printable area to only a few hundred micrometres. Scaling to larger volumes often requires stitching many smaller tiles together that can introduce “proximity effects,” where closely spaced laser spots interfere with one another.

By eliminating the need for conventional lenses, the metalens array enables massive parallelization and turns centimeter-scale 3D printing into a single coordinated and reliable process.These advancements enabled researchers to print millions of microparticles in a day and complete tasks that previously would have required more than a month to finish in just a few hours.

Scalable Adaptive Metamaterials

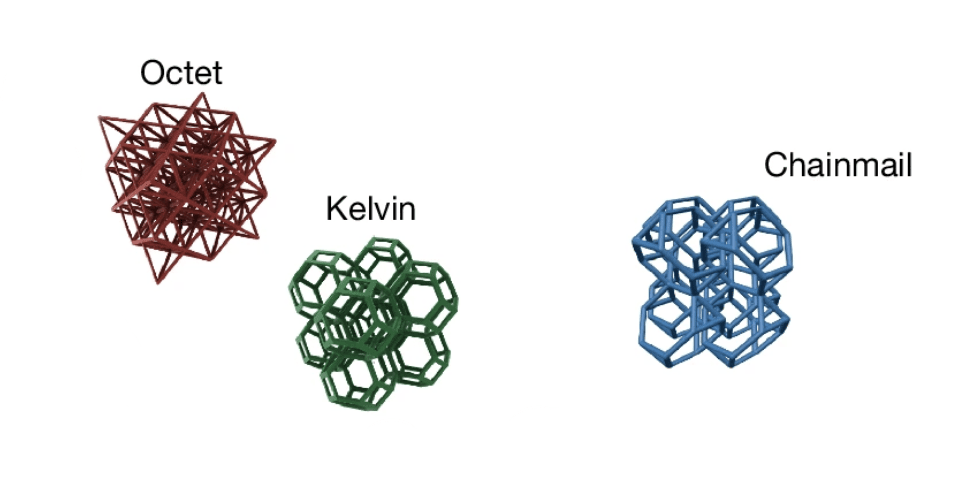

Beyond speed and complex detail, the researchers used the system to fabricate large mechanical metamaterials and engineer structures with desirable properties such as high strength, low weight and programmable responses.

Using the new TPL platform, the researchers produced three types of metamaterials:

- Octet lattices, for stretching

- Kelvin lattices, for bending

- Chainmail lattices, for interlocking

The advancements to print larger sections of these patterns quickly open the door to study how the structures will deform, fracture and fail, which is key information for designing tougher and more resilient materials.

Zhou, along with researchers at Stanford University, contributed to the early design and experimental prototyping of the metalens array.

“This project is a large collaboration that was made possible by the leadership of our collaborators at Lawrence Livermore National Laboratory and Stanford University,” Zhou said. “With UNC Charlotte’s strengths in optics and its established nanofabrication infrastructure, we’re expanding our metasurface research toward a broader range of classical and nonclassical optical applications.”

Read more about the new 3D printing system in the paper published in Nature, along with a Research Highlight in Nature Electronics.